WURST Stahlbau

WURST Stahlbau in Bersenbrück: a local hero sets global (steel) standards. From polar research stations to local football grounds, steel made by Wurst can be found in practically all parts of the world.

It is 1966. England wins the World Cup final against Germany with the disputed Wembley goal; the first episode of the Space Patrol Orion series is being shown on German television; and Hildegard and Friedmut Wurst found a business that repairs agricultural machinery, offers farriery services, makes windows and doors, and includes a metalworking shop as well as plumbing and heating installation. They thus laid the corner stone for a successful steelwork company. Now in 2024, WURST Stahlbau has around 260 employees and produces nearly 20,000 tonnes of diverse steel structures every year on a production area of 15,000 square metres.

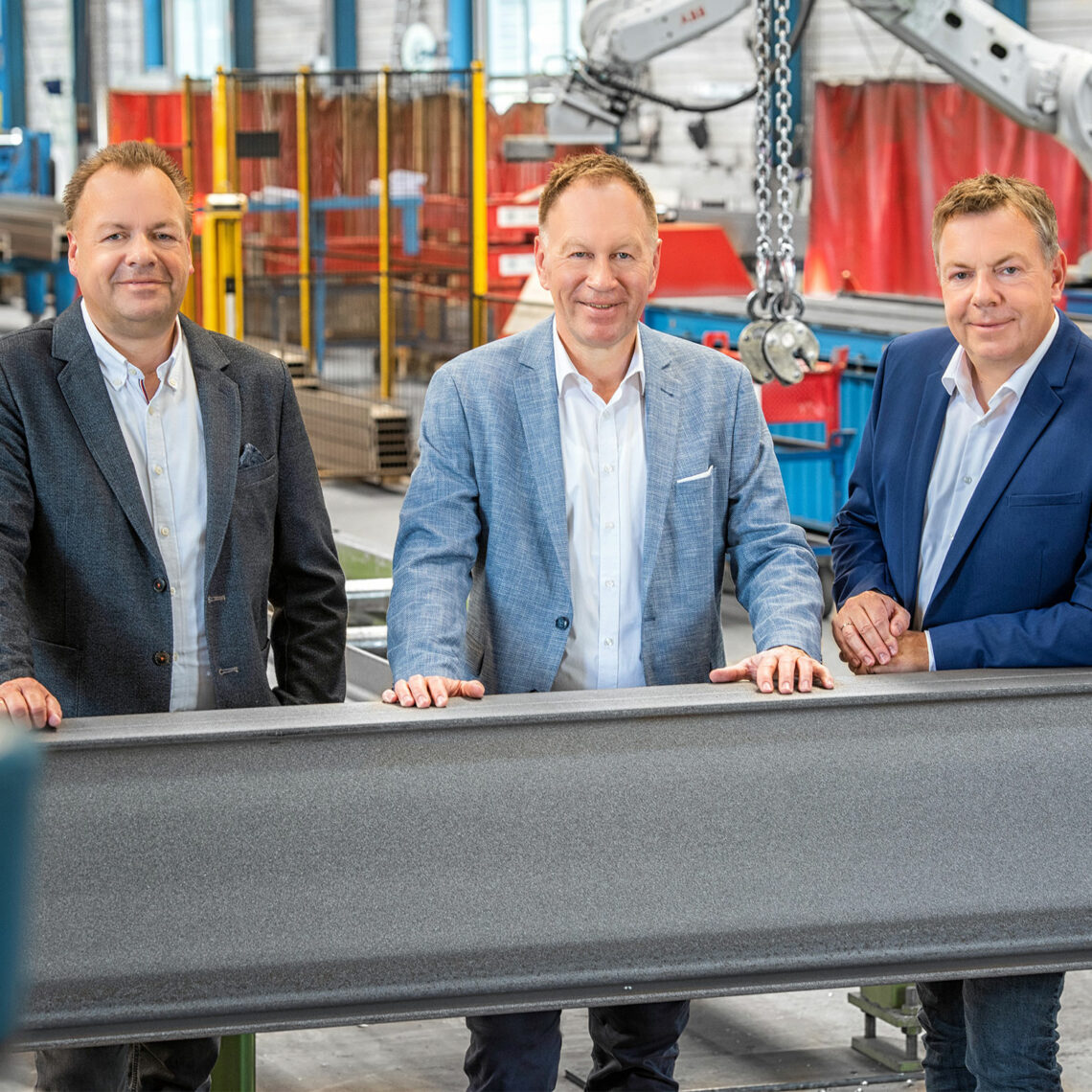

But in fact, the really impressive figure is a smaller, single-digit number. The company is run by three brothers: Christian, Michael and Thomas Wurst.

“We’re in charge of different business units and always work together closely for the trend-setting overall corporate decisi-ons, although we naturally also sometimes have controversial views and opinions,” explains CTO Christian Wurst, who adds, with a smile: “As children, we sometimes had a real set-to, but that also welds us together for life.”

Speaking of welding: WURST Stahlbau sees itself as a 100% skilled crafts business, with corresponding roots that fill the family with pride, as Christian Wurst points out: “When you start off in a small way as our parents did, you’re not afraid of hard work or modest sales. But you stand by your hard work and the entrepreneurial courage that has led to successful growth based on pragmatic, swift decisions.”

Traditional steel construction, innovative product development, close employee relationships

From lawnmowers to aerospace: WURST constructed production buildings for the various versions of the Ariane 5 and 6 space rockets. From windows to research station: WURST supplies the steel structure for the “Neumayer 3” Antarctic research station. Whether for shipyards and shipbuilding, industri-al facilities or football grounds, such as the roof of Werder Bremen’s Weserstadion, products by WURST can be found everywhere – both throughout the region and the world.

“We want to stand out from competitors in terms of quality, aspiration, sustainability and service, with a focus not just on success itself but also on the conditions that generate it,” defines the managing director. The Wurst brothers always emphasise one thing in particular: the team. The blue helmet is a trademark that the employees wear with pride when working on national or international construction sites or in the company’s own production buil-dings in Bersenbrück.

“Further training courses are offered regularly as a standard feature. We also accompany ten trainees and apprentices each year as they start their work-ing life, and almost always take them on once they’ve obtained their qualifications.” As a result, many employees have been with WURST for their entire working life. Finding the next generation of up-and-coming skilled workers has definitely become more difficult, but our “good reputation as an employ-er in the region” means that we always receive qualified applications from motivated young people, explains the company boss.

The company’s willingness to innovate is certainly another valid reason for this. WURST has responded to the regulations issued by many German states to use some of the surface area generated by new car parks for renewable energy systems. For this purpose, PV car park roofing has been developed that allows for electricity to be generated even on sealed areas. To save all the detailed construction planning for every single carport, the new development from Osnabrück District consists of a modular system that can be installed on most car parks without too much earthmoving work. Three different types of carports are currently available, each with a translucent glass roof with PV panels. The electricity generated in this way can be used, for example, by companies for their own production process, or for recharging electric vehicles.

Sustainability as marketing factor

WURST Stahlbau is the first skilled crafts business in Osnabrücker Land to receive the “Wir sind dabei” (we’re taking part) banner. The Lower Saxony Alliance for Sustainability (NAN) awards the banner to companies in Lower Saxony that have verified their special commitment in the ecological, social and economic dimensions of sustainability. More and more companies recognise that sustainability in business is increasingly a question of making themselves fit for the future, and are taking gradual steps to ensure that their production and work processes are environmentally friendly, socially compatible and competitive. The NAN seeks to make these committed companies visible and thus encourage others to follow these good examples, and has developed the “Wir sind dabei” accolade to this end. On implementing measures from a specially drawn up catalogue, companies can use the banner for a period of up to two years.

Commended for knowledge management

Knowledge retention in a company is hugely worthwhile. Individual job-specific knowledge extends from simple combinations of numbers to special skills and complex contexts. The knowledge of individual employees can be lost through natural staffing fluctuations, and also in the future when the baby boomer generation goes into retirement. But a good corporate strategy combined with digital tools allows companies like WURST Stahlbau to safeguard know-how in the long term and put it to good use. WURST Stahlbau therefore works with state-of-the-art management systems in the interests of a sustainable approach to knowledge transfer, among others.

“For us, sustainability is not an empty phrase. On the contrast, it is actually an integral part of our corporate philosophy. We are therefore also proud to part of the Alliance for Sustainability,” says Christian Wurst.

Benefit society as an expression of social commitment

The “good reputation” also comes from the company’s social commitment to initiatives and projects in the region of Osnabrück District. WURST has founded a benefit society called WURST Stahlbau Hilfsprojekte e. V. that works with the food bank, sports clubs or social institutions.

“Our strong roots in our home region mean it is a matter of personal significance for us and part of our corporate culture to provide active support for so-cial projects and associations,” says the businessman.

It is, above all, the needy in the town and region of Bersenbrück that benefit from this commitment, which also provides support together with donations in kind and money for social aid projects and voluntary organisations. These include, among others, the Caritas organisation and Heilpädagogische Hilfe Bersenbrück (remedial centre). It is also worth giving a special mention to the company’s commitment to the Bersenbrück food bank.

As founder and chairperson, it is a matter of the heart for senior boss Hildegard Wurst to help the needy, in the simplest and most effective way possible. She is also a role model for the management team with Christian, Michael and Thomas Wurst. Michael is on the board of Bersenbrück support associa-tion, Thomas is on the board of the trade guild and the state association for the metal trade in Lower Saxony and Bremen, and Christian plays an active role on the board and general assembly of Osnabrück-Emsland-County Bentheim Chamber of Skilled Crafts and as President of the German Steel Association, where he chairs the structural steel forum. The brothers are also members of Bersenbrück voluntary fire brigade, where they are called out around 200 times each year. Most of the workforce follow suit and also work as volunteers with a wide range of different organisations.

WURST Stahlbau is successful not only as a company doing business on the world market, but also in terms of the commitment it shows to the people in the region, both as an employer and with regard to charitable involvement in society at large – as is the case with family-run skilled crafts firms that live up to their responsibility for the economic, ecological and social well-being of their region, every single day.

WURST Stahlbau GmbH

Sie sehen gerade einen Platzhalterinhalt von Standard. Um auf den eigentlichen Inhalt zuzugreifen, klicken Sie auf den Button unten. Bitte beachten Sie, dass dabei Daten an Drittanbieter weitergegeben werden.

Mehr Informationen