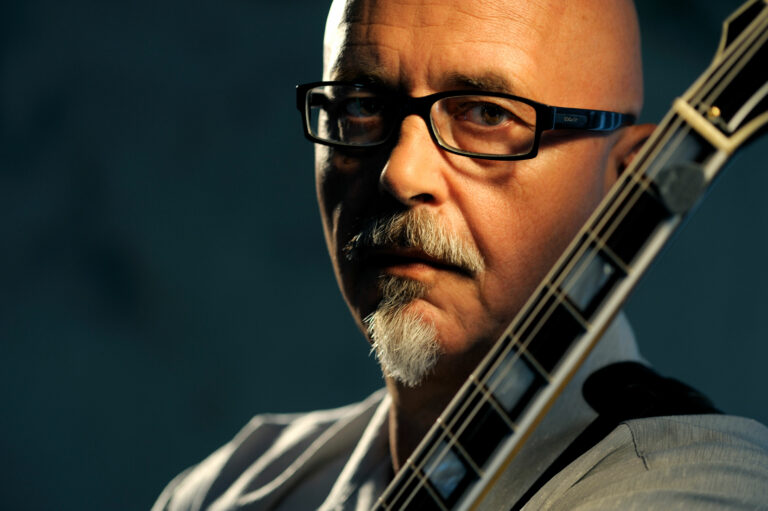

Bernard Krone

Nearly 120 years ago, in 1906, Anna and Bernhard Krone founded a blacksmith’s business which laid the basis for a rapid development. Today, the Krone Group generates turnover of more than three billion Euros and is a leading producer of agricultural machinery and commercial vehicles. Exports of its high-tech machinery, such as the BIG X maize chopper with almost 1100 BHP, go all over the world.

“The way our company has developed is a perfect portrayal of the whole region. The Emsland used to stand for barren soils and difficult farming conditi-ons, but now it is a successful industrial region. The people living here used to be poor, but it was precisely these difficult conditions that brought forth a culture of hard work and persistence,” says Bernard Krone, who runs the family-owned company as chairman of the supervisory board in the fourth ge-neration. This mindset combining a down-to-earth approach with hard work and the pursuit of constant improvement is also what has made the Krone Group successful.

“Hungry for success”

“Hungry for success and striving for improvement” still resona-tes with Krone today, at a time when many feel that growth has reached its limits. “On the contrary, whenever we thought we had it made and could lean back, that’s when we started

to make mistakes,” says Krone, who joined the company management in 2007. It is therefore crucial for him and his staff to keep developing and not wallow in complacency.

This dynamic progress would not have been possible without the courage to make bold decisions. Krone describes his decision making progress as “a mixture of 10 percent head and 90 percent gut feeling.”

You could say this decision-making gene was inherited from his father, particularly when it comes to making mistakes. “If you’re afraid to make mistakes, then you won’t decide anything at all. But constructive criticism and drawing attention to mistakes is a good thing. When customers take a critical look at our products or our processes, that’s when we make progress. That’s why we are not at all afraid of making the wrong decision. My father said that may-be 80 percent of his decisions were wrong. But the 20 percent that were right, were so good that they moved us forward,” says Krone.

Blacksmith in the Emsland

Despite all the modern advancements, Krone remains true to his roots. His father used to refer to himself as the “blacksmith from the Emsland”. Bernard Krone promised his father that he would continue this tradition, even if the Krone Group’s focus today is on developing selfdriving machines and inves-ting in AI applications. Today, the entrepreneur is far more than “just” a blacksmith in a business that was, a few decades ago 90 percent steel and iron. Today, the company is more like a thinktank which is also largely involved in the development of electronics and data software.

In recent decades, the company’s development has taken great leaps forward, above all in digitalisation and automation. While implementing SAP 20 years ago was seen as a pioneering step, according to Krone, today it’s about so much more than just IT systems. “We’re working on platforms that link customers and production,” explains the 47-year-old. “MyKrone.Green” is one such customer platform created by the company. It can be used by cust-omers not only for digital management of their machines, but also provides access to machinery service.

One of the company’s current pioneering large-scale projects is the state-of-the-art parts and logistics centre located on the way into Spelle. An inno-vative warehouse and logistics centre has been built here on around 7.5 hectares of land. The 40 million Euros investment allows the company to make further progress digitalising its processes, and clearly improves the security of supply for farmers and agricultural contractors. “The political crisis and the pandemic have shown us the importance of having a reliable food supply. The new centre not only enhances our logistics capabilities, but also strengthens our position as a reliable partner for the agricultural sector,” explains Krone.

The company’s commercial vehicles division has also made considerable progress with automation, for example, in the production of components such as container doors and bulkheads for semitrailers. This work is done almost completely by robots. It’s not just about the costs, says Krone: “This step was necessary because it was getting increasingly difficult to find skilled workers to do these tasks.” The company therefore invested in robot technology to make sure it could keep its production site in Germany, while at the same time safeguarding jobs in the region long term. However, politicians have a duty to ensure stable framework conditions so that this remains possible.

Regional roots – international success

Although the Krone Group has strong regional roots, it operates on a broad international basis with an export rate of 72 percent with activities in more than 70 countries. Although Germany remains its most important market, followed by Europe in general and the EU in particular, Krone is also strongly represented across the Atlantic. The USA in particular is a highly dynamic market with great growth potential. Here the company has two large branches, in Olive Branch, Mississippi and Reno in Nevada, as well as numerous retail stores. Altogether more than 100 people work for Krone in the USA. Krone has also established structures in Brazil and Argentina in recent years which further strengthen the company. The Krone-Trainingcenter Latin America in Brazil, for example, ensures that customers in South America no longer have to make the long journey to Europe for training. Despite the challenges of trading restrictions and financial problems in some South American countries, Krone sees great opportunities in these markets.

Skilled workers as the basis

The skilled workforce provides the basis for the company’s international growth. More than 6,000 employees ensure Krone’s worldwide success. App-renticeships represent one of the fundamental aspects, with 539 apprentices currently active in the Krone Group. Bernard Krone knows himself what that means. At the age of 19, he did a CCI apprenticeship as an industrial mechanic for machinery and systems engineering in Schleswig-Holstein, and learnt what work is all about. Although it was a culture shock at first, looking back he sees it as an incredibly satisfying experience.

He is still highly appreciative of training to this day. “Anyone can start their career with an apprenticeship at Krone,” he says. He actively encourages the personal and professional development of his employees, offering financial support for part-time degree courses, or opportunities to gain international experience. He thinks early career guidance is very important “because young people are often simply unaware of all the career possibilities that exist.”

Adventure playground in Spelle

He himself took time to grow into the company. “As a child, I saw the factory in Spelle mainly as a huge adventure playground, and not necessarily the place where our workers earned their living or where the products for our customers were made,” recalls Krone. Now and then he earned a bit of pocket money with a holiday job, and sometimes even wondered why on earth he was still actually going to school. “But my father always said: ‘You’re learning for yourself, so that other people will take you seriously.” And this is how Krone made his way from the adventure playground in Spelle to the top of a globally successful business. At the same time, normality and a down-to-earth approach are things he still finds important. In the end, he explains, suc-cess is a joint effort. And this success comes with societal obligations.

Emsland in a good position

Volunteer work plays an important role for him, not least for his home region in particular. This is why Krone is committed to the further development of the region, in roles that include chairing the “Wachstumsregion Ems-Achse e. V.” (association for regional economic growth), or taking part in the CCI general assembly. “Even though the Emsland is definitely in a good position right now, there are still a few areas that need work – literally.” One project that is really close to his heart is the four-lane upgrade of the European route E 233. “It takes several decades to plan this kind of work, and you have to make sure you’ve got the people on board. In the end, the project will have great added value for the general public and, above all, for the economic development of the region,” says Krone. “I’m not speaking especially about our company, even though one of our sites is located directly on the E 233. The upgrade doesn’t mean we’ll sell a single additional semitrailer, but it will make it more pleasant and safer for everyone using this main road.” The project also offers scope for considering ecological concerns. This matters to him as well, with sustainability becoming ever more important to the cor-porate philosophy.

Farmers invented sustainability

“Sustainability is nothing new. You could actually say it was first invented by our customers, the farmers. It is firmly integrated in every farmer’s DNA. It’s the customers who show us what living sustainably means, not the other way round,” he explains. In that sense, the company also tries to work sustain-ably. This includes, for example, prioritising materials procured in the region, in order to avoid long journeys and the resulting carbon emissions. As a result, more than 80 percent of the production materials for agricultural machinery comes from within a radius of around 120 kilometres from the main factory in Spelle. These measures are documented in the sustainability report, which Krone first published in abridged form in 2019 and which is now available in comprehensive digital form in 2024. The report provides details of the company’s progress in terms of energy efficiency, material usage and staff development. Reducing the carbon footprint is particularly important in the commercial vehicles division in order to fulfil the requirements of cust-omers and, above all, EU regulation.

By balancing tradition with innovation, regional roots with global alignment, and dynamic development with sustainability, Bernard Krone is leading the company into a future that is as promising as it is challenging. This is exactly what makes him and the Krone group a beacon in the region.

Maschinenfabrik Bernard KRONE GmbH & Co.KG

Sie sehen gerade einen Platzhalterinhalt von Standard. Um auf den eigentlichen Inhalt zuzugreifen, klicken Sie auf den Button unten. Bitte beachten Sie, dass dabei Daten an Drittanbieter weitergegeben werden.

Mehr Informationen